Share this

Laser Ablation – Peak Power and Energy Considerations

April 3, 2020

Precision Laser Ablation:

Precise removal of thin layers requires tight control of the laser parameters of energy, energy stability and spatial uniformity. When specifying an ablation system, it is useful to determine the “process window” for the materials to be ablated.

The process window is the energy range which produces appropriate material removal, i.e. acceptable results. Energy below this range does not ablate adequately and energy above this range damages or ablates excessive material. The sum of the energy stability and spatial uniformity must not exceed the process window in order to achieve good results. In addition, accurate control of the nominal energy, which can be provided by a digitally controlled attenuator, is critical for predictable results. For these applications, more energy is not necessarily better due to the fact that excess energy decreases the effective resolution.

A Customer Case Study:

We received feedback from a customer recently who was having difficulty adjusting to the correct energy. The nominal energy setting was 3% of the max energy. The attenuator provided a very linear adjustment range from 0 to 100%, with 0.1% resolution. One step therefore changed the energy from 3.0% to 3.1%, a change of 3.3% in the nominal energy.

The process window was rather tight so this made optimizing the energy difficult. Had the max energy been only twice the process window, the result would be much more accurate. If the nominal setting was 50%, then one step would be 50.1%, which is only a 0.2% change in the nominal energy. The effective resolution would then be over 16 times higher. For optimum results, systems should be specified with a maximum energy of no more than twice the expected process window.

Energy (joules) = average power (watts) / repetition rate (hertz) Laser Fluence = energy / area

For pulsed lasers, pulse repetition rate is a determinant of energy. Laser fluence, or target energy density, is the optical energy delivered per unit area of your work surface.

Laser ablation offers performance and productivity advantages in a range of life science and industrial applications, but there are energy considerations unique to your application:

Industrial

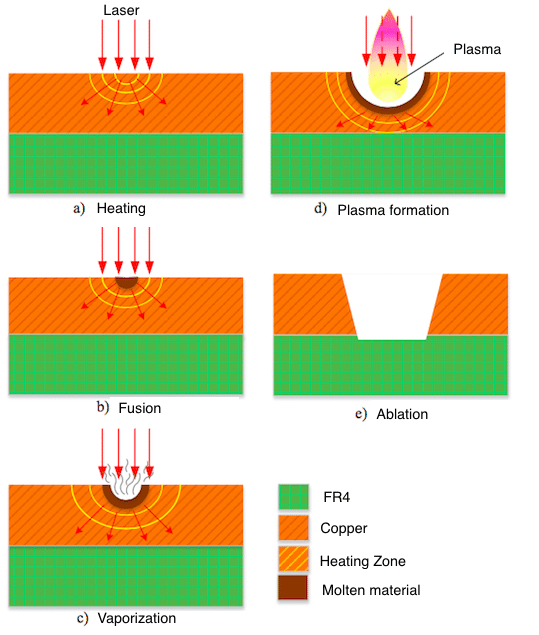

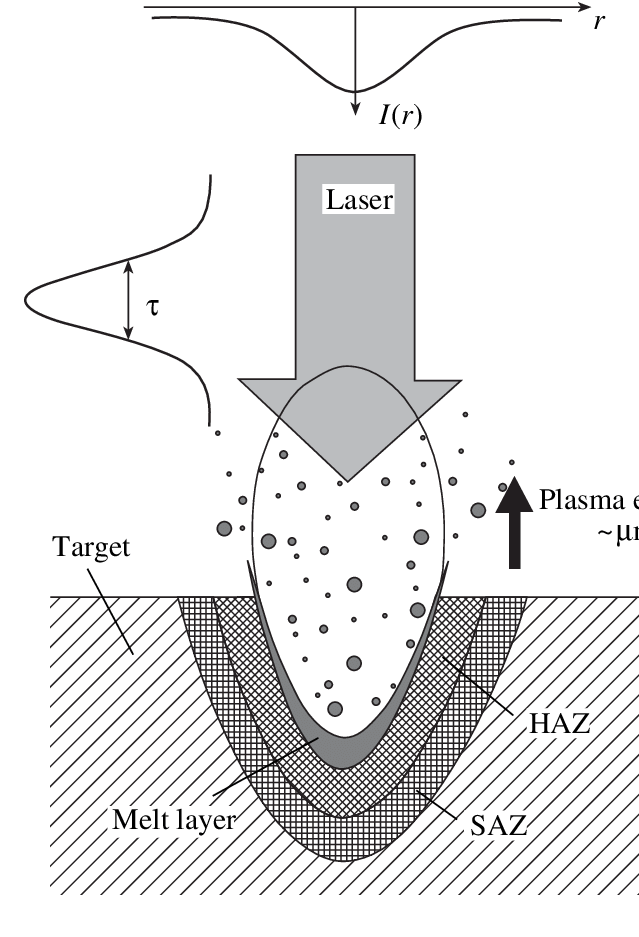

Energy requirements vary widely depending on material, melt vs. vaporization and spot diameter of the work surface. Material removal begins at the ‘ablation threshold’, and as fluence increases, more material is removed per volume until it reaches a threshold, at which point additional energy transforms to heat, which can cause secondary thermal effects without additional removal of material.

Dental laser

Longer wavelengths present challenges that can require additional components such as wave guides in the handpiece.

Energy requirements depend on treatment of hard or soft tissue. Energy requirements for removal of sulcular epithelium in treatment of periodontal disease requires less than ½ the energy needed for surgical excision.

Ophthalmic

The therapeutic window is the ratio of threshold power required to create a rupture to that required for treatment (producing a mild lesion). The width of the therapeutic window must be sufficient to accommodate for variations in pigmentation.

If you know your process window parameters, give us a call so we can help you select one of our Jewel series lasers or systems to give you the best results.

--

Source

https://www.dentistrytoday.com/ce-articles/381-lasers-in-dentistry-an-overview

https://web.stanford.edu/~palanker/publications/Ophthalmic_Laser_Therapy.pdf

Share this

- photonics (19)

- Lasers (12)

- DPSS Lasers (10)

- pulse delay generator (8)

- pulse generator (8)

- LIDAR (4)

- Lasers and Optics (4)

- Technology (4)

- Laboratory Science (3)

- Nd:YAG Lasers (3)

- PIV (3)

- Science (3)

- Spectroscopy (3)

- custom laser systems (3)

- Aerospace studies (2)

- Commercial Lasers (2)

- LIBS (2)

- Laser Induced Breakdown Spectroscopy (2)

- Laser Research (2)

- Laser Science (2)

- Particle Image Velocimetry (2)

- Pulsed Lasers (2)

- custom lasers (2)

- laser ablation (2)

- laser system (2)

- Biotech (1)

- COVID (1)

- Cancer (1)

- Cancer Diagnostics (1)

- Cancer Research (1)

- Current Generators (1)

- Dentistry (1)

- Emerald Pulse Generator (1)

- Flame Kernel (1)

- High Current Pulse Generator (1)

- Ignition and Combustion (1)

- Ignition flame kernel (1)

- Laser Dentistry (1)

- Laser Manufacturing (1)

- Laser Soldering (1)

- Laser Tooth (1)

- Laser aerospace (1)

- Laser photonics (1)

- MDA (1)

- Mass Spectroscopy (1)

- Micro Soldering (1)

- PIV Laser (1)

- Physics (1)

- Research (1)

- Surface mounted technology (1)

- ablation (1)

- artemis nasa (1)

- blue lasers (1)

- delay generator (1)

- er marketing (1)

- laser attenuator (1)

- laser modules (1)

- laser quality (1)

- laser sales and marketing (1)

- laser synchronizer (1)

- lasers for botanical safety (1)

- lasers for cannabis (1)

- lasers purity (1)

- lasers space (1)

- lunar mission 2021 (1)

- lunar missions (1)

- nasa lasers (1)

- nasa payload (1)

- oem lasers (1)

- photonics sales and marketing (1)

- system synchronizer (1)

- February 2024 (1)

- October 2023 (1)

- December 2022 (1)

- November 2022 (2)

- July 2022 (1)

- May 2022 (1)

- March 2022 (1)

- January 2022 (1)

- December 2021 (2)

- November 2021 (2)

- September 2021 (1)

- August 2021 (1)

- July 2021 (2)

- June 2021 (1)

- May 2021 (2)

- April 2021 (1)

- March 2021 (3)

- February 2021 (1)

- January 2021 (2)

- December 2020 (1)

- November 2020 (2)

- October 2020 (2)

- September 2020 (4)

- August 2020 (3)

- July 2020 (3)

- June 2020 (4)

- May 2020 (2)

- April 2020 (6)

- March 2020 (3)

- February 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (2)

- September 2019 (1)

- August 2019 (2)

- May 2019 (1)

- April 2019 (1)

- February 2019 (1)

- October 2018 (2)

- September 2018 (2)

- August 2018 (2)

- July 2018 (1)

- June 2018 (1)

- April 2018 (1)

- March 2018 (1)

- February 2018 (1)

- January 2018 (1)

- December 2017 (2)

- September 2017 (3)

- July 2017 (2)

- June 2017 (2)

- March 2017 (4)

- January 2017 (2)

- November 2016 (2)

- September 2016 (2)

- August 2016 (1)

- May 2016 (1)

- April 2016 (1)

- March 2016 (2)

- December 2015 (2)

- October 2015 (2)

- September 2015 (1)