Share this

Laser Ablation (LALI) in Inspection: An Interview with Jeff Williams, CEO, EXUM Instruments

February 11, 2021

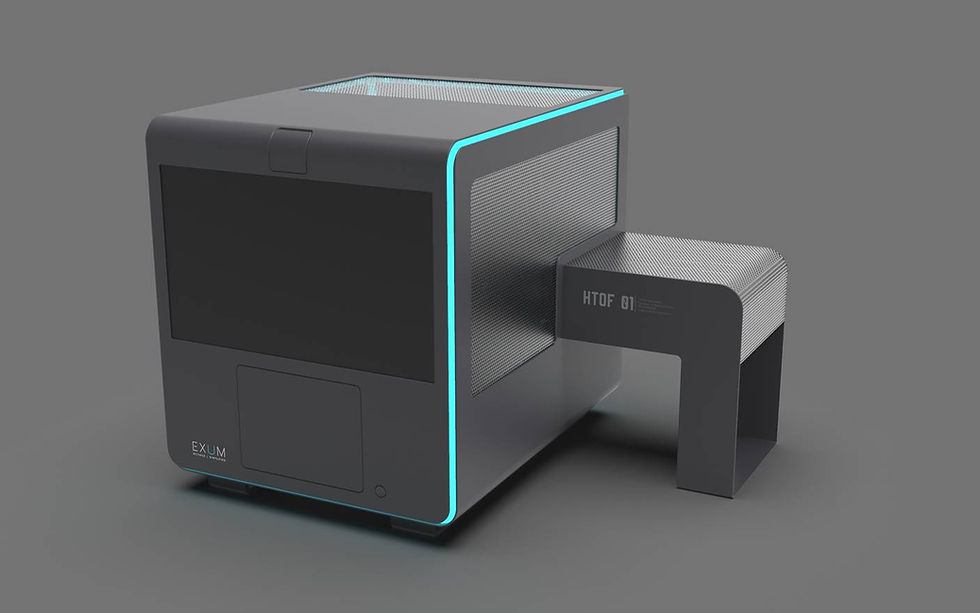

Jeff Williams, CEO of EXUM Instruments, shares his experience working with Quantum Composers to develop the Massbox™ OEM Laser, the first Laser Ablation Laser Ionization Time of Flight Mass Spectrometer (LALI-TOF-MS) instrument on the market.

What brought you to Quantum Composers?

Our requirements for an aperture image laser delivery system are very stringent and also pretty out of the ordinary as far as the optical design is concerned. We had a lot of really tight specs to hit, from small apertures and long working distances, good video output, and light issues. After about a year of trying to outsource this, and also trying to do it internally, we turned to Quantum Composers because of their years of experience. We presented them all the challenges we had and they said they could do it. There's definitely been a lot of iteration and prototyping and learning involved. But ultimately, they were able to deliver a system that hit all of our specs for the ablation delivery system for the Massbox.

Quantum Composers made it very easy to integrate an external system into an OEM environment because of the way that they build their systems. They are very OEM friendly and have helped to make it an easily integrated solution. The Massbox is a generalized instrument so that any solid sample can be analyzed and we can quantify anything you want in there very easily. You don't need a Ph.D. in order to run our tool. We can stand it up in the morning, and by the afternoon, you're going to be operating the same day, the same way you will three months from now. The ablation system designed by Quantum Composers is critical to this capability.

Where have you seen the most success with the Massbox laser ablation system?

We’ve seen a lot of interest and success in metals analysis for metals, manufacturing, and aerospace engineering, as well as in gem and mineral resources.

You’re also entering the cannabis and CBD market. Tell me about that.

Because of the need for quality controls in cannabis manufacturing, we're method development for it. But it can be used for quality control for raw flower, as it's coming off of the farms or growth facilities, to test for heavy metals. There is an issue right now in the cannabis industry at large with high levels of heavy metals, especially lead and cadmium. This is causing a lot of recalls, especially in the CBD market. So we're trying to be a solutions tool for ease of use of heavy metals analysis, right there in the flower. The Massbox can be used for any solid sample.

Pharmaceutical R&D is also a great fit for the Massbox, and of course, a critical need in the market today.

Laser ablation has been popular in academic communities for some time. What are the challenges to bringing it to these types of applications?

We're trying to approach this differently than other instrument manufacturers who tend to sell a tool and expect their users to figure out the nuances of how to use it and how it applies in their labs. We have integrated all of our experience from a ton of different instruments, and generalizing that experience, such that the software package can walk through what the user wants to do to make it a very easy transition to where we should be able to tell you what to do, as you're going to put your sample into getting your final results out, as opposed to months of application development and method development.

The Massbox is currently the only commercial instrument using laser ablation laser ionization (LALI) technology. There are advantages to this technology, especially when it comes down to ease of use and quantification. Our system doesn’t rely on carrier gases that introduce a little bit of a dynamic nature to the system, which results in system changes over time, requiring you to constantly retune and re-standardize. Our instrument stays very static throughout long periods of time, making it much easier to quantify because you get a more stoichiometric representation of what the samples are made of. In other words, you get a better representation of atom for atom and what's actually there. So we see what the calcium-to-iron ratio is, that's going to be pretty close to what it truly is in the sample, as opposed to having to go through a really complex standardization. By using a Time-of-Flight mass spectrometer, we get a full mass spectrum at every single laser shot, whereas with a lot of techniques, you have to sweep through the mass range so you're not getting the full picture.

The Massbox also differentiates with its plug-and-play design and ease of use. Do you expect this eventually to move from the lab into the rest of a facility to test samples?

It could, in situations where that makes sense. It has a very small footprint, just over 2’x2’x2’, and it only has one power cord on the back of it. Nothing else is required for the instrument to operate safely in any environment. It could very easily just be put on a cart rolled around and plugged in wherever you need it. Most of the time, this lives on a lab bench and stays there. But it absolutely has the capability for field mobile analysis, on an oil rig for example. Its compact size and sophisticated integration are critical to its usability.

What has it been like to work with Quantum Composers on this project?

Our relationship with Quantum Composers is very collaborative as well as foreseeing possible issues before they come up. They always do their best to make sure that they're delivering on the specs that they say and are willing to iterate into it until they get it right. Their pricing has been very reasonable and competitive. And they've always been available to answer my really annoying daily phone calls.

I've had a good experience with them. If we have something go wrong, they're pretty quick to fix the mistake and make sure it doesn't happen again.

What's next for you?

We're going to be focusing on the ramp-up of the Massbox, and constantly iterating and shipping new versions of our software package. Ultimately, we're going to be developing new instrumentation and software products for a 2022 launch.

Quantum Composers designed and built a custom OEM 1064/266nm beam delivery for EXUM Instruments Massbox.

Learn more about our laser capabilities.

Share this

- photonics (19)

- Lasers (12)

- DPSS Lasers (10)

- pulse delay generator (8)

- pulse generator (8)

- LIDAR (4)

- Lasers and Optics (4)

- Technology (4)

- Laboratory Science (3)

- Nd:YAG Lasers (3)

- PIV (3)

- Science (3)

- Spectroscopy (3)

- custom laser systems (3)

- Aerospace studies (2)

- Commercial Lasers (2)

- LIBS (2)

- Laser Induced Breakdown Spectroscopy (2)

- Laser Research (2)

- Laser Science (2)

- Particle Image Velocimetry (2)

- Pulsed Lasers (2)

- custom lasers (2)

- laser ablation (2)

- laser system (2)

- Biotech (1)

- COVID (1)

- Cancer (1)

- Cancer Diagnostics (1)

- Cancer Research (1)

- Current Generators (1)

- Dentistry (1)

- Emerald Pulse Generator (1)

- Flame Kernel (1)

- High Current Pulse Generator (1)

- Ignition and Combustion (1)

- Ignition flame kernel (1)

- Laser Dentistry (1)

- Laser Manufacturing (1)

- Laser Soldering (1)

- Laser Tooth (1)

- Laser aerospace (1)

- Laser photonics (1)

- MDA (1)

- Mass Spectroscopy (1)

- Micro Soldering (1)

- PIV Laser (1)

- Physics (1)

- Research (1)

- Surface mounted technology (1)

- ablation (1)

- artemis nasa (1)

- blue lasers (1)

- delay generator (1)

- er marketing (1)

- laser attenuator (1)

- laser modules (1)

- laser quality (1)

- laser sales and marketing (1)

- laser synchronizer (1)

- lasers for botanical safety (1)

- lasers for cannabis (1)

- lasers purity (1)

- lasers space (1)

- lunar mission 2021 (1)

- lunar missions (1)

- nasa lasers (1)

- nasa payload (1)

- oem lasers (1)

- photonics sales and marketing (1)

- system synchronizer (1)

- February 2024 (1)

- October 2023 (1)

- December 2022 (1)

- November 2022 (2)

- July 2022 (1)

- May 2022 (1)

- March 2022 (1)

- January 2022 (1)

- December 2021 (2)

- November 2021 (2)

- September 2021 (1)

- August 2021 (1)

- July 2021 (2)

- June 2021 (1)

- May 2021 (2)

- April 2021 (1)

- March 2021 (3)

- February 2021 (1)

- January 2021 (2)

- December 2020 (1)

- November 2020 (2)

- October 2020 (2)

- September 2020 (4)

- August 2020 (3)

- July 2020 (3)

- June 2020 (4)

- May 2020 (2)

- April 2020 (6)

- March 2020 (3)

- February 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (2)

- September 2019 (1)

- August 2019 (2)

- May 2019 (1)

- April 2019 (1)

- February 2019 (1)

- October 2018 (2)

- September 2018 (2)

- August 2018 (2)

- July 2018 (1)

- June 2018 (1)

- April 2018 (1)

- March 2018 (1)

- February 2018 (1)

- January 2018 (1)

- December 2017 (2)

- September 2017 (3)

- July 2017 (2)

- June 2017 (2)

- March 2017 (4)

- January 2017 (2)

- November 2016 (2)

- September 2016 (2)

- August 2016 (1)

- May 2016 (1)

- April 2016 (1)

- March 2016 (2)

- December 2015 (2)

- October 2015 (2)

- September 2015 (1)